Revolutionary 3D Printing Technique Could Change Manufacturing Forever!

Imagine a world where 3D printing not only creates intricate shapes but also produces materials stronger than anything we've seen before. That's becoming a reality thanks to groundbreaking research from Daryl Yee and his team at EPFL’s School of Engineering.

Vat photopolymerization has been a popular method in the 3D printing world, using light-reactive liquid resin to create objects. However, its limitations have held it back from unlocking its full potential. The issue? The materials created are often porous, leading to reduced strength and excessive shrinkage. That's where Yee’s innovative approach comes into play.

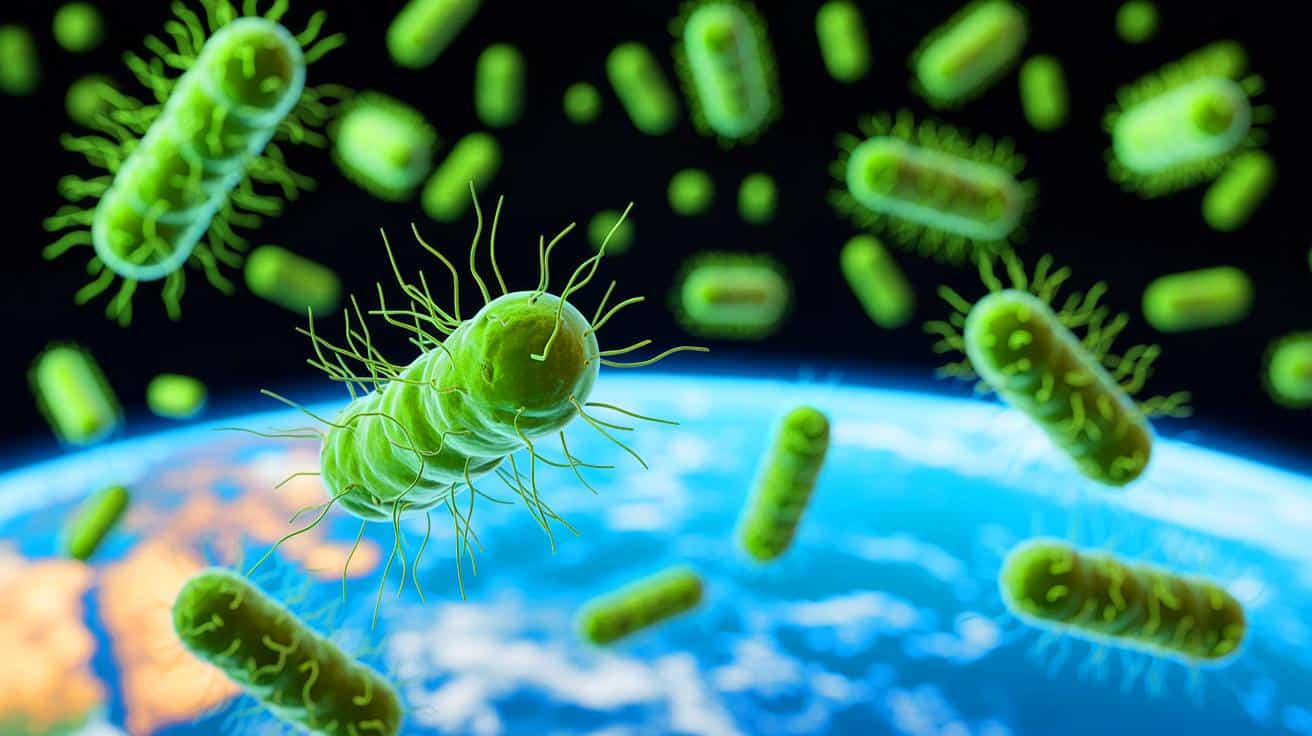

Instead of relying on traditional methods that mix resin with metals, the team has flipped the script. They start by 3D printing a lightweight framework using a simple water-based gel, known as hydrogel. This blank structure is then soaked in metal salts that are chemically converted into tiny metal nanoparticles, distributed throughout the gel. With multiple cycles of this process, they can create composites with an impressively high metal content.

What’s the outcome? After removing the hydrogel through heating, you're left with a dense metal or ceramic object that mirrors the original shape of the gel. This innovative method not only allows for a variety of metals and ceramics to be produced from the same hydrogel template but also opens doors to new possibilities in 3D printing.

In their recent publication in Advanced Materials, Yee explains, “Our work not only enables the fabrication of high-quality metals and ceramics with an accessible, low-cost 3D printing process; it also highlights a new paradigm in additive manufacturing where material selection occurs after 3D printing, rather than before.”

The team’s capacity to create complex structures called gyroids out of metals like iron, copper, and silver showcases their technique’s strength. Remarkably, their materials could endure 20 times more pressure than those produced with prior methods, along with only 20% shrinkage compared to the usual 60-90%!

This research is particularly promising for industries needing lightweight yet strong materials, such as sensors, biomedical devices, and energy technologies. Just think of the implications for metal catalysts that help convert chemical energy into electricity or for cooling systems in energy technologies.

Looking to the future, Yee's team is excited about refining their process further, aiming to enhance the density of their materials and speed up production. They’re even exploring robotics to automate and streamline these infusion steps, potentially revolutionizing manufacturing as we know it.