Breakthrough in Hydrogen Fuel Cell Technology Promises Enhanced Durability for Heavy-Duty Vehicles

In the quest to develop sustainable transportation solutions, the limitations of traditional battery systems for trucks and heavy-duty vehicles have become increasingly evident. These vehicles, which often traverse long distances, require frequent and lengthy charging stops, making them less efficient for operations that demand continuous travel. However, recent advancements in hydrogen fuel cell technology present a promising alternative that could revolutionize long-haul trucking.

A team of researchers at the University of California, Los Angeles (UCLA) has made significant strides in this field, particularly in extending the lifespan of hydrogen fuel cells. Led by Yu Huang, a professor of materials science and engineering at the UCLA Samueli School of Engineering, the research team has developed a new catalyst design that could potentially increase fuel cell lifespans to an impressive 200,000 hours. This figure is nearly seven times higher than the U.S. Department of Energy's (DOE) target for 2050, indicating a major leap forward in fuel cell viability for heavy-duty applications.

Published in the esteemed journal Nature Nanotechnology, this research represents a crucial step toward the broader adoption of fuel cell technology in heavy-duty vehicles, such as long-haul tractor trailers. Although medium- and heavy-duty trucks only comprise about 5% of vehicles on the road, they are responsible for nearly a quarter of greenhouse gas emissions from automobiles, as reported by federal estimates. This statistic highlights the enormous potential for fuel cell technology to make a substantial impact in reducing air pollution and promoting cleaner transportation.

One of the key advantages of fuel cells over traditional battery systems is their significantly lighter weight. This characteristic not only facilitates increased fuel efficiency but also makes them more suitable for heavy-duty vehicles that typically carry large cargo loads. The new catalyst designed by the UCLA team boasts a projected power output of 1.08 watts per square centimeter, providing performance levels comparable to conventional batteries that can be up to eight times heavier. Such differences are crucial for the trucking industry, where weight-to-power ratio can greatly influence efficiency and operational costs.

Moreover, building a comprehensive national hydrogen refueling infrastructure could potentially require less financial investment than establishing an extensive electric vehicle charging network. Hydrogen fuel cells operate by converting the chemical energy stored in hydrogen into electricity, with water vapor being the only byproduct of this clean energy process. This feature has positioned them as a favorable choice for environmentally-friendly transportation solutions. However, one of the main challenges has been the slow chemical reactions involved in energy conversion, necessitating the use of effective catalysts to achieve faster reaction rates.

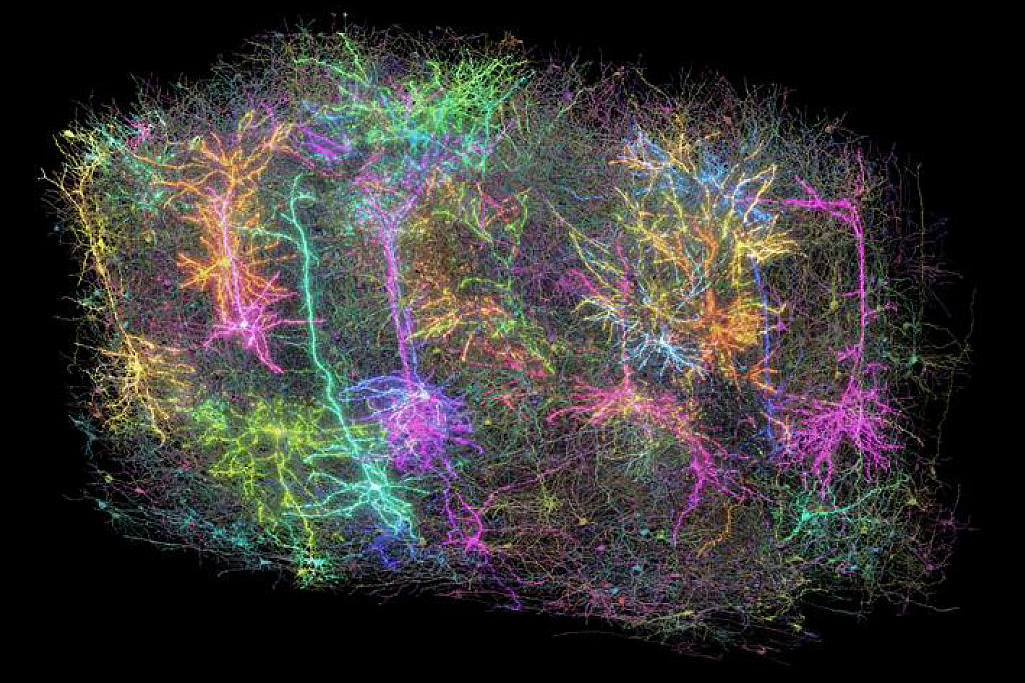

Historically, platinum-alloy catalysts have demonstrated superior performance for hydrogen fuel cells; however, they suffer from rapid degradation as alloying elements leach out over time. This degradation is exacerbated by the high voltage cycles typical of heavy-duty vehicles. To tackle this issue, the UCLA research team has innovated a durable catalyst architecture that protects platinum from the common pitfalls seen in alloy systems. Their approach involves embedding ultrafine platinum nanoparticles within protective graphene shells. Graphene, known for being incredibly thin yet strong and highly conductive, serves to shield these nanoparticles from degradation.

These graphene-encased nanoparticles are further integrated into the porous structure of Ketjenblack, a unique carbon material, creating a "particles-within-particles" architecture. This innovative design not only ensures long-term stability but also maintains the high catalytic activity necessary for efficient fuel cell performance.

Yu Huang emphasized the importance of durability for heavy-duty fuel cell systems, given their operation under harsh conditions for extended periods. He stated, Our pure platinum catalyst, enhanced with a graphene-based protection strategy, overcomes the shortcomings of conventional platinum alloys by preventing the leaching of alloying elements. This innovation ensures that the catalyst remains active and robust, even under demanding long-haul conditions.

The research team conducted an accelerated stress test that simulated years of real-world driving by subjecting the catalyst to 90,000 square-wave voltage cycles. Impressively, the catalyst exhibited a power loss of less than 1.1%, while a 10% loss is generally considered exceptional in the industry. Such results suggest that the new catalyst could lead to fuel cell lifetimes exceeding the remarkable 200,000 hours, vastly exceeding the DOE's target of 30,000 hours for heavy-duty proton exchange membrane fuel cell systems.

In addition to addressing the dual challenges of catalytic activity and durability, the innovative catalyst design by UCLA researchers represents a significant advancement for hydrogen-powered heavy-duty vehicles. This technological breakthrough is crucial for reducing emissions and enhancing fuel efficiency within a sector that consumes a substantial share of transportation energy.

Building upon their previous successes including the development of a fuel cell catalyst for light-duty vehicles that achieved a lifespan of 15,000 hours, nearly doubling the DOEs target of 8,000 hours the UCLA research team has set a new standard for what is achievable in this field. The study's lead authors, Zeyan Liu and Bosi Peng, both Ph.D. graduates from UCLA, were mentored by Huang, whose research group specializes in the development of nanoscale building blocks for complex materials, particularly in fuel cell catalysts.

Other contributors to the research include Xiaofeng Duan, a professor of chemistry and biochemistry at UCLA, and Xiaoqing Pan, a professor of materials science and engineering at the University of California, Irvine. Both Huang and Duan are affiliated with the California NanoSystems Institute at UCLA. The study also involved contributions from Yu-Han Joseph Tsai and Ao Zhang from UCLA, as well as Mingjie Xu, Wenjie Zang, XingXu Yan, and Li Xing from UC Irvine. Furthermore, UCLA's Technology Development Group has filed a patent for this groundbreaking technology.

As the transportation sector continues to evolve, these advancements in hydrogen fuel cell technology pave the way for a future where sustainable and efficient long-haul trucking is not just a possibility but a reality.